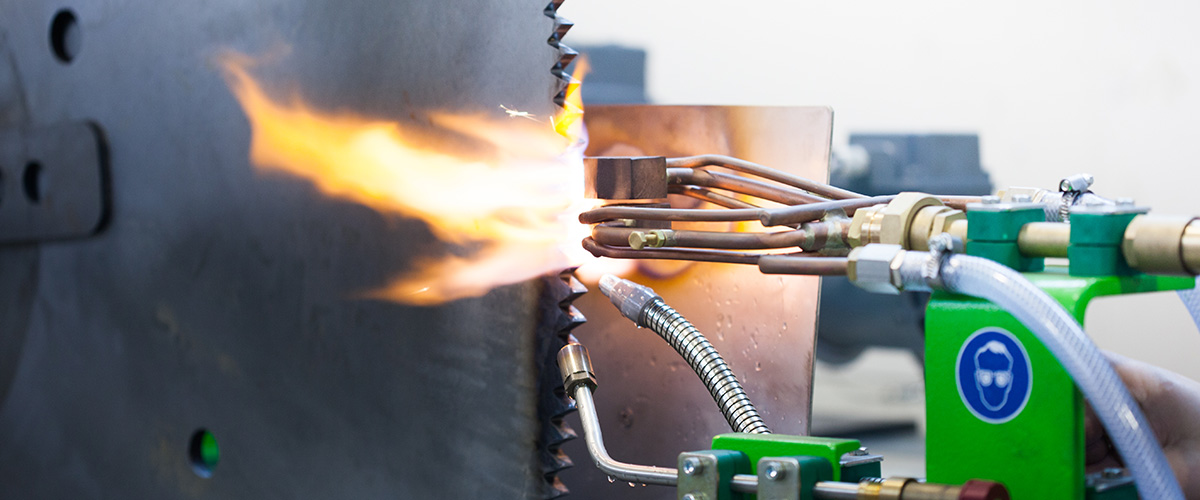

Parallel® AutoFlame 2500

Tooth Tip Hardening Machine for Hot and Friction (Cold) Saw Blades

Features

- For tooth tip heat treatment of saw blade diameters 1200-2500 mm, thickness – 16mm with flame hardening

- Extremely robust structure for long lasting, trouble free operation with minimum maintenance requirements because of a sturdy machine frame made as a welded assembly, closed loop water cooling for the burner, splash protection sheets made of stainless steel and generously sized gear motor

- Easiest adjustment and operation with no particular skill required

- Unique burner design warrants reliable warning of the tooth tip to the spot with excellent visibility to the conversion process

- Quick machining of the saw blade given by high cycle and advance speeds

- Highly flexible thanks to adjustability of the burner/quench unit in 2 axes and inverter controlled adjustability of the saw blade rotational speed

- Reliably prevents surface hardening of the tooth gullets and ensures reproducibly high hardening results (substantially superior to the induction hardening process)

- 2 quench systems alternatively selectable so that blades made from all common materials can be processed

Specification

- Saw blade size 1200 x 8 mm – 2500 x 16 mm

- Method of heat treatment: flame hardening

- Burner with integrated water cooling

- Can be operated optionally with natural gas or bottled gas (Propane/Butane) plus Oxygen

- 2 quench systems installed (with plain water or water/air spray)

- Capacity: approx. 10-30 saw blades per 8h shift

- Dimensions: approx. 2500 x 1200 x 2000 mm (l x w x h) – excluding cylinder bundle (for gas/Oxygen)

- Weight: approx. 1500kg

- Total installed capacity: approx. 1 kW/380 V/50 Hz

- Compressed air supply approx. 4-7 bar (required for spray quench option, only)

- Standards: EN, VDE and DIN

Options

- manual tooth tip hardness tester